With a continued focus on quality cetane measurement, CFR Engines has developed the next generation of the Ignition Quality Tester (IQT®) line of Constant Volume Combustion Chamber (CVCC) instruments, the IQT XLM.

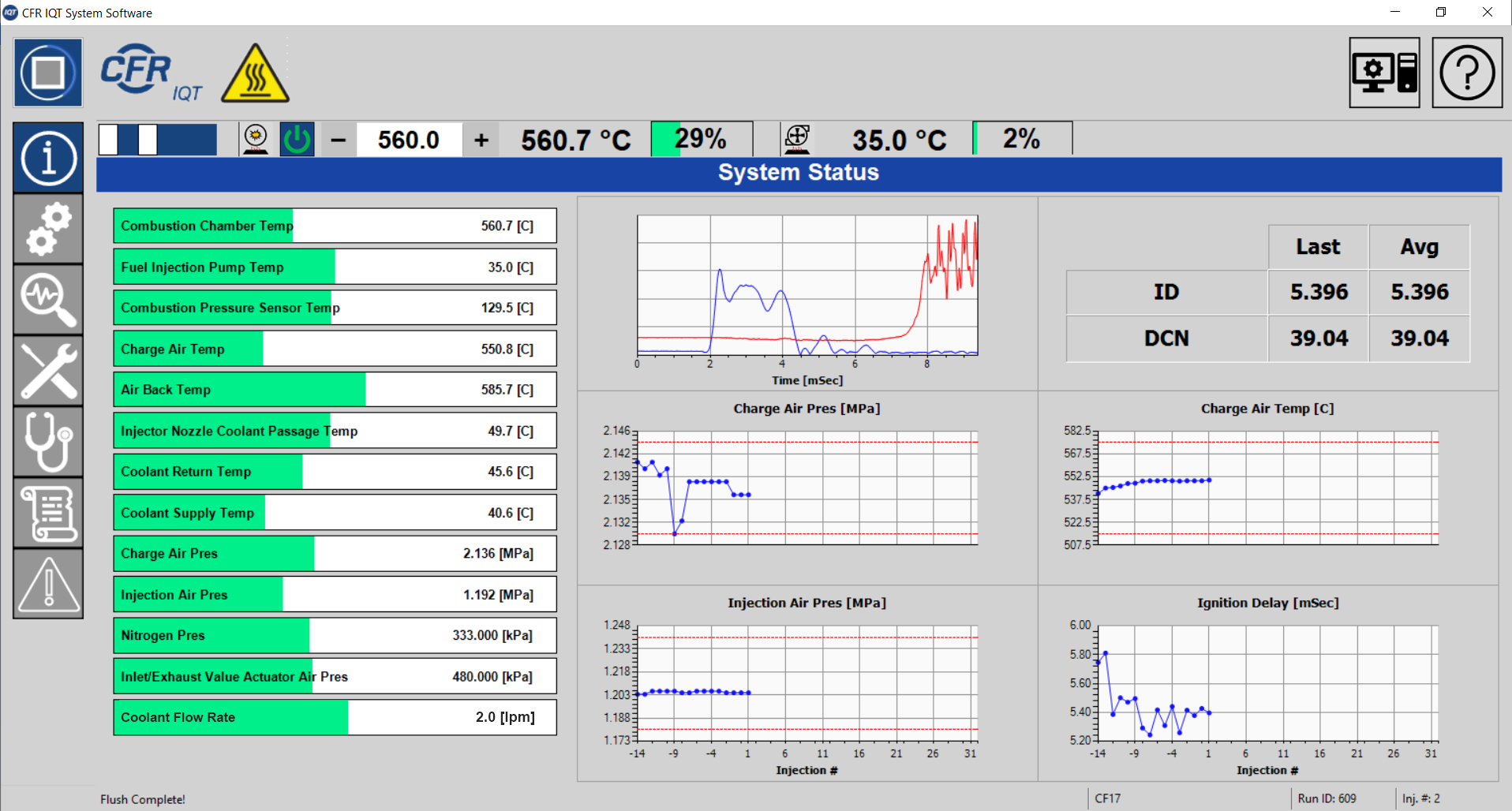

The next generation IQT is supported by an enhanced software package. While maintaining the same basic functionality as the existing IQT software, the enhanced IQT-XLM software includes a new touchscreen-compatible user interface, multi-language capability, improved self-diagnostic features, support for LIMS integration, and simplified access to test results and instrument logs.

Ease of Use & Structure

Users of the new IQT XLM user interface will experience streamlined operational performance due to the use of easy-to-use graphical toolbars instead of a complex menu system. The user experience has also been further improved with the application of Windows’ multitasking capability – performing a DCN test no longer prevents the operator from simultaneously using other features such as reviewing test result logs or viewing instrument diagnostic displays. The calibration of sensors during annual maintenance has also been simplified – all sensors can be calibrated from the same screen, and reference values can be entered in a wide range of pressure and temperature units (psi, bar, kPa, °F, etc.) so that manual conversion of units is avoided.

Multiple Language Capabilities

To improve the experience of operators around the world, the IQT-XLM now provides multi-language capabilities, including the use of symbols and the ability for an operator to select text-based elements such as labels and data table headings in English, Spanish, German, and Simplified Chinese.

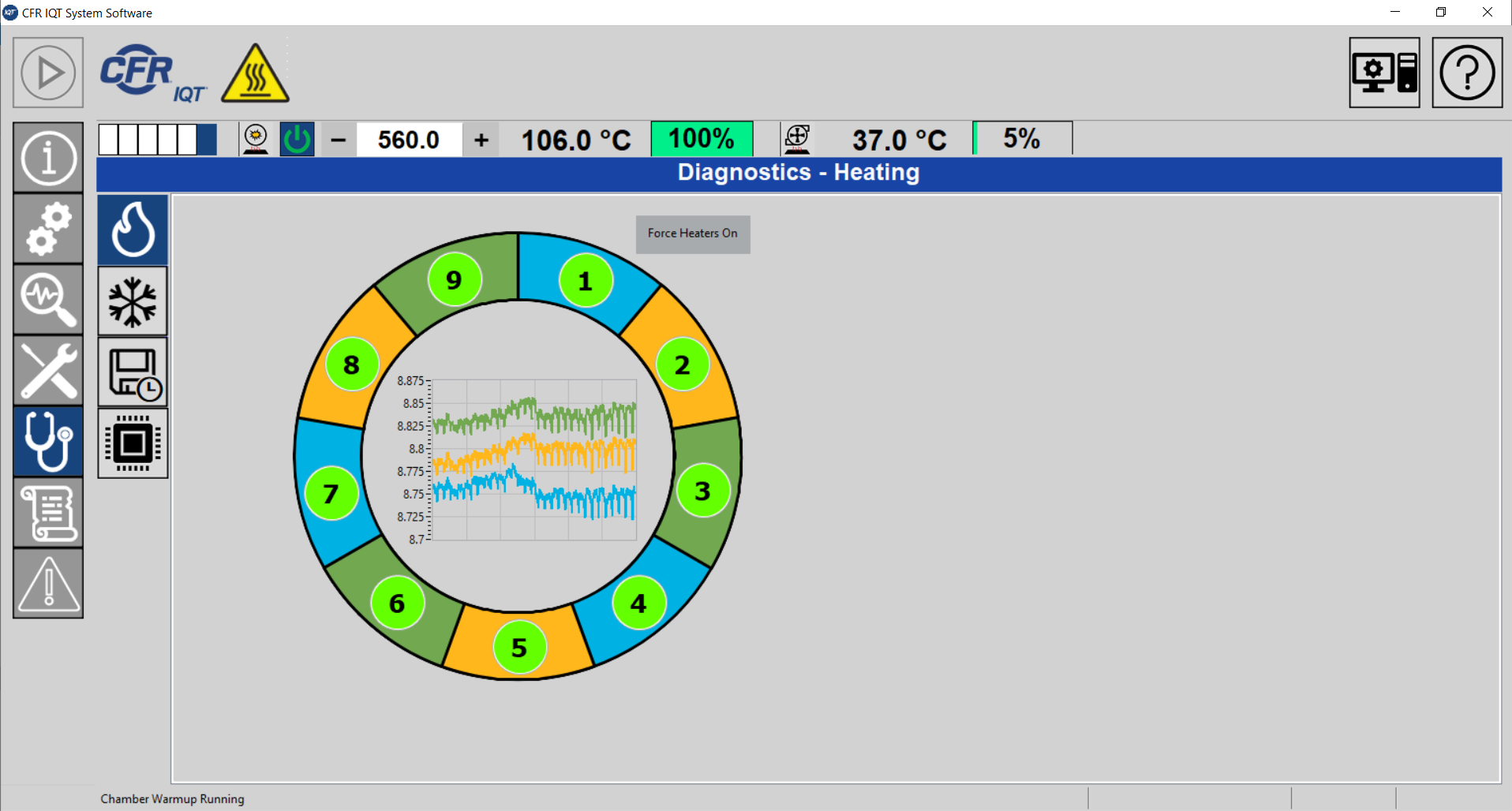

Advanced Diagnostics

The IQT-XLM has an enhanced modular data acquisition system that allows for the installation of additional sensors to provide expanded status monitoring and diagnostic capabilities. All the system parameters specified in the ASTM and CEN standard test methods are now instrumented, displayed on-screen, and logged as part of the test results.

Chamber Heater Monitoring

Monitoring of the status of the combustion chamber heaters in the IQT-XLM has been significantly improved – the feature is now fully integrated into the software and the status of each chamber heater is monitored and displayed separately.

Cooling System Diagnostic Monitoring

A separate cooling system diagnostic monitoring system has been implemented, which displays more detailed information such as circulation pump and radiator fan speeds and multiple coolant temperatures and pressures.

Logged Test Results & LIMS Integration

The existing IQT application’s detailed logging of test results and instrument status has been continued with the new IQT-XLM application, along with several key improvements. The legacy Access database has been replaced with a modern SQLite database. All data from the warm-up portion of a test run is saved for diagnostic purposes, and the test results and instrument log display panels now include a calendar control that allows the operator to browse through those logs rapidly and easily. In addition to creating a PDF test report sheet for each test run, LIMS integration is supported by the application also creating a CSV test summary file for each test run.

Building upon a solid legacy of quality cetane measurement, the new IQT-XLM takes performance to the next level with the support of an enhanced software platform that enables operator efficiency, system flexibility, and expanded monitoring, diagnostic, and reporting capabilities.